News

-

What is the function of the drive motor iron core?

What is the function of the drive motor iron core? In the field of electric motors, the interaction between the stator and rotor is crucial for efficient operation. At the heart of this interaction is the drive motor core, a fundamental component that has a significant i...Read more -

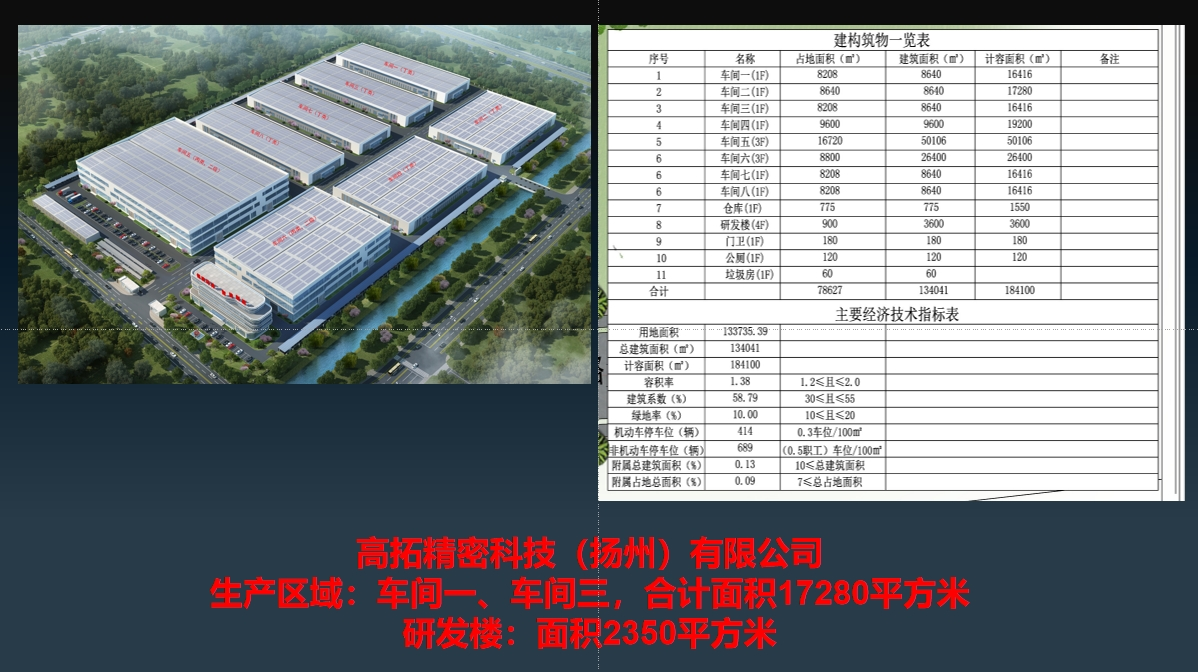

Established A New Factory – Gator Precision Technology (Yangzhou) Co., Ltd

In order to better serve the increase in production capacity in the second half of the year and the subsequent development of our company, our company established a new factory - Gator Precision Technology (Yangzhou) Co., Ltd. in Yangzhou on March 29, 2023. The following...Read more -

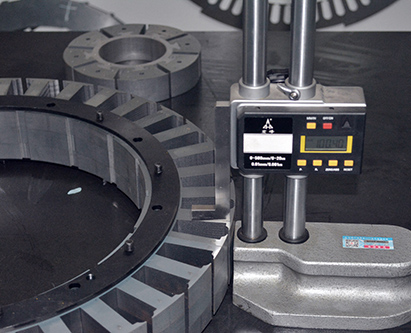

Modern Stamping Technology For Motor Stator And Rotor Core Parts

Motor core is the core component of the motor and also known as magnetic core, which plays a pivotal role in the motor and can increase the magnetic flux of the inductor coil and achieve the maximum conversion of ele...Read more -

6 Problems In Manufacturing Of Stator Cores

With the increasingly detailed division of labor in the motor manufacturing industry, a number of motor factories have taken the stator core as a purchased part or commissioned outsourcing part. Although the core has a full set of design drawings, its size, shape and mat...Read more -

Why Is A DC Motor Core Made Of Laminations

A DC motor consists of two main components: a rotor and a stator. The rotor has a toroidal core with slots for holding the coils or windings. According to Faraday’s law, when the core rotates in a magnetic field, a voltage or electric potential is induced in the coil, an...Read more -

Basics Of Stator And Rotor Structure Of 3-phase Asynchronous Motors

An electric motor is a kind of electrical equipment that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor’s magnetic field and electric current in a wire winding to generate force in the form of tor...Read more -

3 Benefits Of Stator Laminations

A stator makes your engine even the world go round. During the rotation, the stator generates an electromagnetic field that flows from north pole to south pole and charges the engine’s battery. Have you even noticed that the stator core isn’t a piece of solid metal, but ...Read more -

Technical requirements for stamping technology in the production of motor laminations

What are motor laminations? A DC motor consists of two parts, a “stator” which is the stationary part and a “rotor” which is the rotating part. The rotor is composed of a ring-structure iron core, support windings and support coils, and the rotation of the iro...Read more -

3 Control modes commonly used in servo motor

Servo motors are generally controlled by three circuits, which are three closed-loop control negative feedback PID control systems. PID circuit is the current circuit and implemented inside the servo controller. The output current from the controller to the motor is base...Read more -

Differences between stepper motor and servo motor

There are many types of motors available on the market, such as ordinary motor, DC motor, AC motor, synchronous motor, asynchronous motor, geared motor, stepper motor, and servo motor, etc. Are you confused by these different motor names? Jiangyin Gator Precision Mold Co...Read more -

Growing demand for high-efficiency motors creates demand for novel motor lamination materials

There are two types of motor laminations available on the market: stator laminations and rotor laminations. Motor lamination materials are the metal parts of the motor stator and rotor that are stacked, welded and bonded together. Motor laminate materials are used in the...Read more -

Causes and preventive measures of burrs produced by motor core lamination

The quality of core lamination of turbine generator, hydro generator and large AC/DC motor has a great impact on the quality of the motor. During the stamping process, burrs will cause turn-to-turn short circuit of the core, increasing core loss and temperature. Burrs wi...Read more